Mining Method

The most viable way to recover the ore body is by a well-established underground mining method called block caving. Block caving is safe, environmentally sound, and cost-effective for mining a large, deep orebody.

In block caving, a large section of ore is initially undercut by drilling and blasting, causing it to collapse under its weight. The blasted ore breaks apart and falls into a series of pre-constructed funnels and access tunnels to form ore extraction drawpoints. From the drawpoints, ore will pass through a series of handling systems to an initial crushing circuit underground before transferring to the above surface Concentrator Complex.

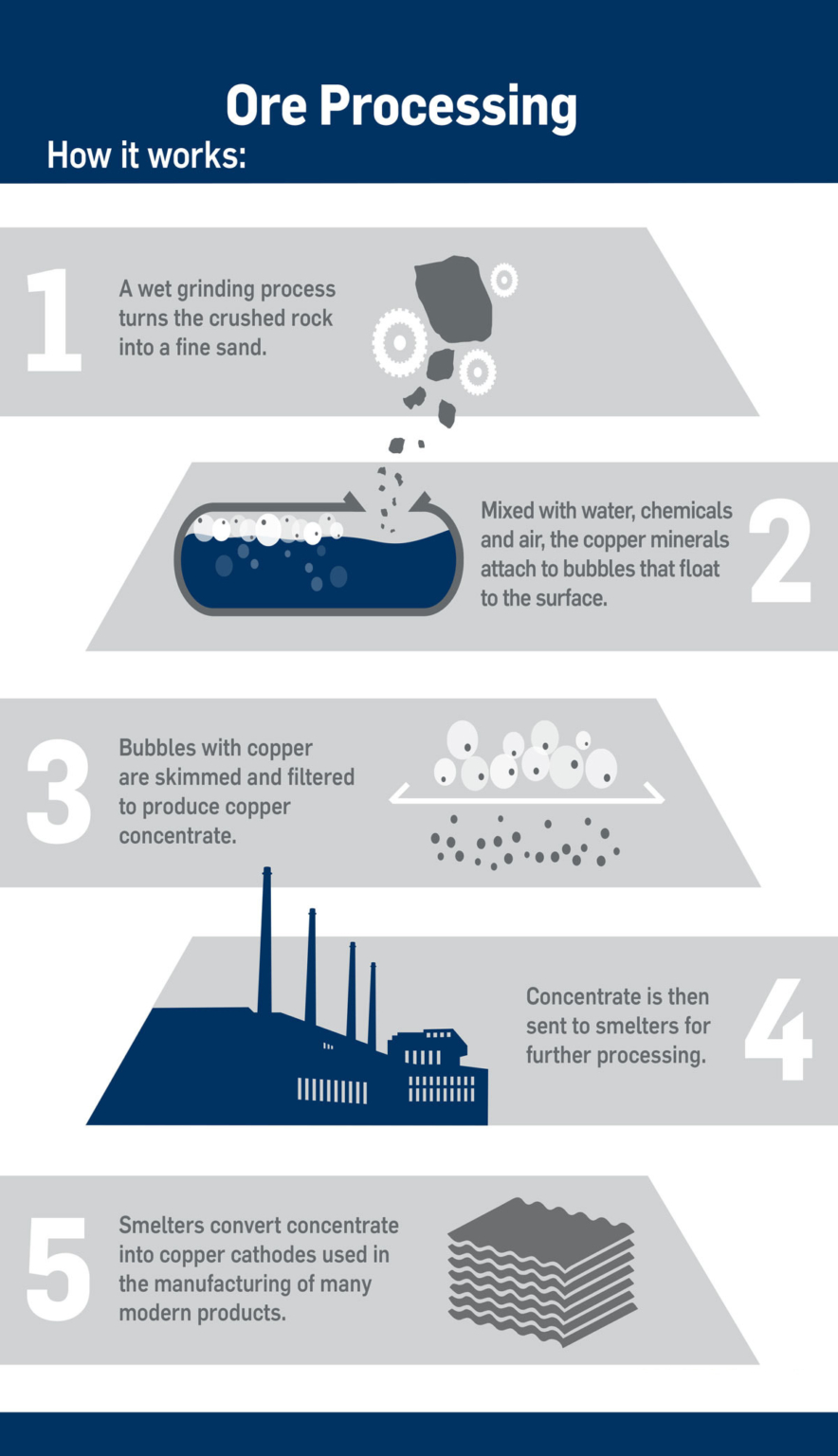

Concentrating

In the second step of the production process, we convert the ore from a low-grade material into a concentrate of high-grade copper inside the Concentrator Complex.

The technique all begins with a wet grinding process that turns the crushed ore into a slurry and transports it to flotation cells. When mixed with water, reagents, and air, the copper minerals produce a bubbly froth. The bubbles with copper are skimmed and filtered to produce copper concentrate.

The concentrate, which contains about 29-31% copper, will then be sent to customers for further processing.

Smelting and Refining

When the concentrate leaves our facility, it will complete the smelting and refining phases to separate the copper from other metals. The final result is a 99.999% pure copper cathode, which is an essential raw material for the processing industry. Copper originating from 7,000 ft below the surface will eventually find its way into electrical wiring, electronics, power generation and transmission, automotive applications, and antimicrobial medical products.